What’s WEP?

Posted on: Dec. 29, 2022, 11:56 p.m.

I'll let you in on a secret right away WEP stands for Web Electronic Prototype and is the first platform in Italy that allows you to manage the production of your cards easily and quickly, without wasting time and without having to exchange 1000 emails with suppliers electronic.

With WEP, 5 simple steps will suffice to launch the assembly of your electronic boards:

1 Upload or create the list of components (BOM, Bill Of Material)

2 Check availability and choose the method of supply

3 Upload documentation and name your project

4 Proceed by creating an order from your project

5 Choose the payment method and send your cards to work, they will soon be real

Let's see them one by one

1. Upload or create the BOM,

In this phase you can upload your BOM of any format, to find out more read our article on how to make a BOM properly and find out everything you need to know. You will become faster than Bolt in the 200m!!

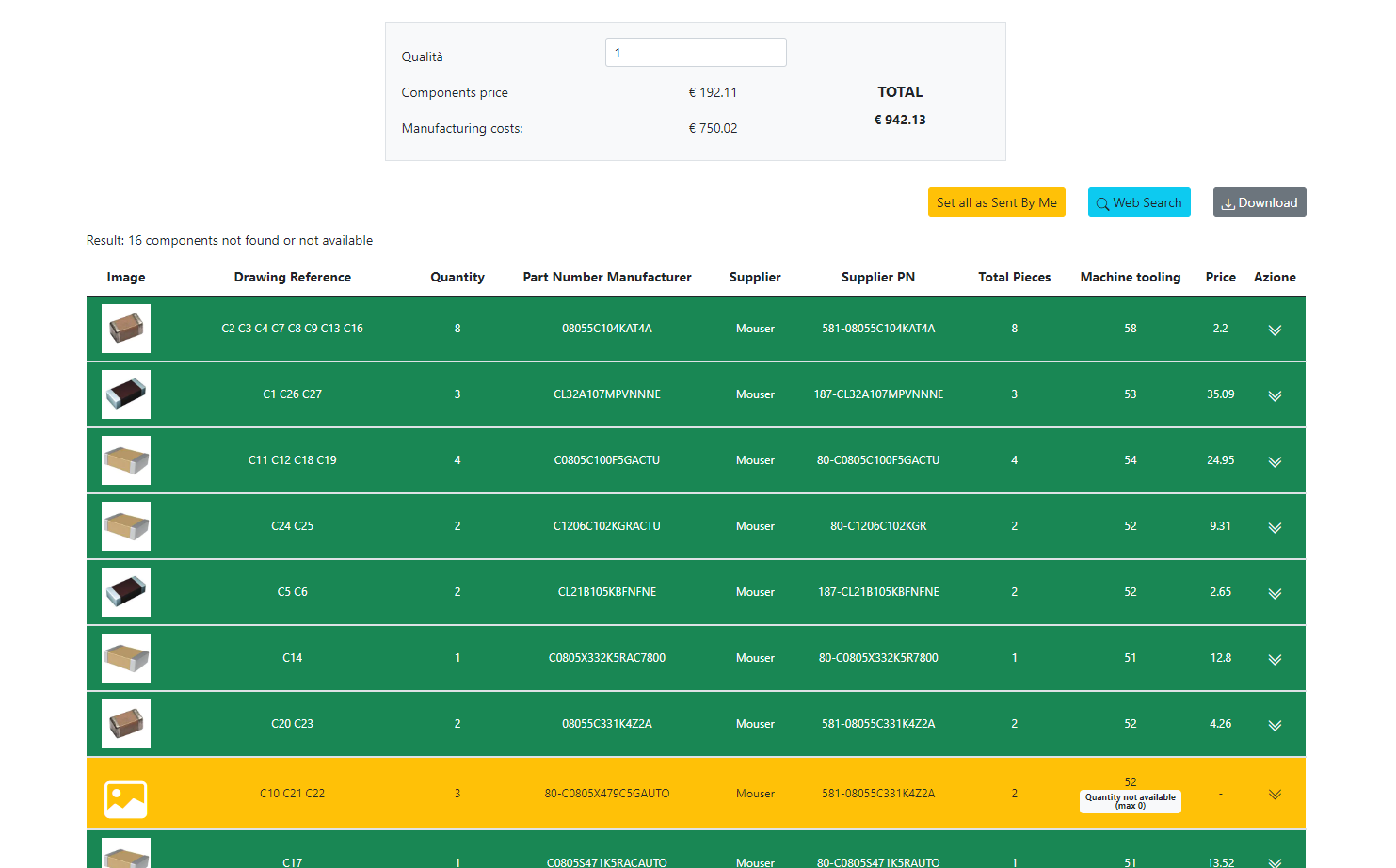

2. Check availability and choose the method of supply

You will also be able to manage this critical phase in complete autonomy, without useless e-mail exchanges.

WEP is connected in real time with one of the largest online distributors of electronic components in the world: Mouser from which you can directly buy everything you need, without additional costs, you got it right ... the price of the components that you will find on our site is exactly the one shown At Mouser we don't add any fees.

If you wish, you can choose the components and send them to us, you don't have to buy them from us! We are not interested in selling components but in getting to assemble your boards as quickly as possible.

You know when the employee who follows your electronic card is sick. .sound familiar to you?Our software do not get sick and can not mutual! You can go about your business at any time of the day or night!

What benefits can you get?

- In less than the blink of an eye you will know the exact cost of the tau BOM, updated in real time

- You will identify the most suitable component during the design, replacing it with a click

You will immediately get the answers you are looking for, the platform will give you information in real time that nobody gives you.

Try calling your current supplier and have them quote you a list of materials 5 or 6 times…

He should do this job giving you a lot of time, for free, without being sure that you will go to him to assemble the boards, or that you will complete the project.

At this stage you can also decide to order your PCBs, we will also make those, you will no longer be forced to contact multiple suppliers.

As for the components, you can decide, even for the printed circuits, whether to order them through WEP or supply them to us. . .the important thing is that you will no longer have limitations or impositions, only you will decide.

3. Upload of documentation

It's the thing you should be most jealous of in the world, more than your girlfriend or your wife!!

Do you really want to send your projects, the fruit of months of work, your business with carrier pigeons? With the risk that it could fall into the hands of the competition?

It's a bit like a cash-in-transit company instead of an armored car, bulletproof vests and holstered pistols making its guards cycle around in Bermuda shorts and flip-flops in the sun.

WEP will reserve you a protected area where you can jealously keep all the documentation.

Here you can give your project a name and everything that will be used to produce the electronic boards will always refer to a single project in an unambiguous way so that you can be sure not to run into errors dictated by someone else's negligence.

4. Confirm your order

We have reached the final stages, in this phase you will be able to check everything again in a comfortable screen where all the details of the project will be reported, you will be able to change the quantities and obtain final quotes in real time!

You will also be able to decide the quantity of printed circuits to be made, if you have decided to purchase them via WEP and they do not necessarily have to be identical to the number of prototypes to be assembled.

You may want to produce more circuit boards for a variety of reasons:

For example, do you foresee that in the future you will want to make other identical boards and thus decide to reduce costs by producing a greater number and eliminating the fixed costs of a double production or you need only the printed circuit boards for electrical tests.

We will repeat it ad nauseam: the important thing is that you will no longer have limitations or impositions, only you will decide and you will get all the information on costs in real time!

This will help you make the best decisions for your job.

Once launched, your order will fly straight into our systems like a NASA rocket.

From now on, you pass the baton to us.

Before going to SMt line and proceeding with the production of your electronic boards, however, we will check all the compatibility between documentation and components. We will analyze the manufacturing feasibility and possible errors of your printed circuits.

We want to check that everything can proceed for the best and then give you order confirmation.

If there were any inconsistencies we will communicate them to you without collecting the payment and looking together for the best solution for the final objective:

Produce and deliver your electronic boards in the shortest possible time.

Pay attention: Your project will remain saved in your personal area and you can reorder it as many times as you want as it is:

If you need to mount other identical boards to a previous order, most of the work will have already been done.

After a check on the supply of components, always automatically, and after making your choices on which components to buy back, whether to have the printed circuit boards produced again or if you have left over from the previous time

you can reorder your cards with just a few clicks.

5. Choose the payment method and send your cards to work, they will soon be available.

The last step to be able to work your cards is the choice of the payment method, we offer you more solutions.

- Credit card or PayPal account: You can decide to pay the full amount by credit card or through your PayPal account: this is the method recommended by us and with less risk, before being able to place the order, whether it is a new project or a reordering of an existing project, you should check the availability of the components if you have chosen to purchase via WEP. Especially in the last period the quantity of electronic components available is very volatile. By paying with this method we will be able to place your order for the purchase of components instantly without risking losing even one

- Bank Transfer: If you want you can still choose to make the payment by bank transfer, you will receive an e-mail with all the information to make your transfer, in this case we reserve a few days, waiting for the credit to be credited, to purchase the components electronic devices if you have chosen to purchase even only part of them via WEP, unfortunately with the risk of losing someone should they become unavailable for the reasons described above, but don't worry, we have a solution for this too. . .

- Mixed method: If you choose to pay by bank transfer, we give you the opportunity, in order not to risk that the availability of the components you want to purchase changes in a few days, to pay for the components only by credit card or PayPal account. In this way we will be able to instantly purchase the electronic components and there will be no shortage problems, for assembly and printed circuits you can easily make the transfer with the detailed information you will receive via e-mail or by reading the summary page after the payment.

Having talked about payment, you are surely wondering:

How much does all this goodness of GOD cost?

You'll be happy to find out that this innovative method is also COST SAVING! It will allow you to save.

You must be thinking that the one above is the classic expression of someone who wants you to believe that their product is better than the others and costs less. Today you have the opportunity to discover a different way to get better results without stress and wasting time and money.

Why did I write that the working method we have devised will allow you to save money? . . . Mainly for 3 reasons:

1. 1. Containment of pre-production costs and optimization of timing.

2. 2. Cutting-edge technologies to save a lot of time

3. 3. Containment of production waste

1. Containment of pre-production costs and optimization of timing

Working in this way not only benefits you but it's a godsend for us too, otherwise we wouldn't have chosen to change course.

This method allows you to have collected and standardized documentation, in formats that are more congenial to the cutting-edge machinery we use.

In the previous article we talked about productive slots. Through the WEP platform we are able to keep an eye on all delivery dates and have plenty of time for more accurate production planning that maximizes our firepower.

Like? . . . because the process is automatic and we no longer have to respond to each customer individually

We can use our resources to plan activities and focus on production rather than sending an avalanche of emails a day.

2. Using cutting-edge technologies you can save a lot!

A classic cost item in the production of electronic boards is the silk-screen or stencil frame which has costs in the hundreds of euros (read the dedicated article .. )

At WEP we use innovative techniques and machinery which, deriving from 3D printing technologies, allow us to apply the solder paste in the appropriate areas without needing to produce any screen printing frame. This cuts costs and saves time.

It is an extraordinary technology that also has other advantages, in fact it allows you to assemble microscopic components which is often not possible with a normal screen printer. The same technology is also used by Apple in its production lines.

This solution is also perfect in the prototyping field because, if you need to modify your printed circuits, you won't have to worry about spending more money to produce new stencils.

Another way to save money is to reduce waste and with our method it is possible… even for components, you will find out in the next point.

3. Containment of production waste

I'll give you a gift, you're about to find out that you're constantly wasting money using the old system and you don't know it.

Have you ever heard of machine waste?

How many components do your suppliers throw away?

During the production of electronic boards carried out with machines for the automatic positioning of the smd components ( pick & place ) it is essential to discard a certain quantity.

there are suppliers who don't even bother informing you about this matter. Others explain it to you, working in good faith, but calculate the extra quantity of components to purchase by the hand and without precision.

We use a precise method to calculate how many components will be rejected which takes into account several factors and statistics.

You will well understand that the more precise you are, the less waste there will be, the more money you will save. Our system does it instantly and automatically.

But we thought we'd give you the chance to RESET THIS WASTE

In fact, the discarded components will be returned to you so that you can reuse them in your laboratory for any tests or repairs if you wish.

To recap

reduction of management costs + total reduction of the construction costs of the screen printing frames + recovery of machine waste

=

BIG SAVINGS FOR YOU

In a flash with WEP you will be able to:

1. Save time and avoid constant email back-and-forth with your suppliers.

2. Save money by leveraging the best technologies currently out there.

3. Manage all the pre-production phases of your cards independently.

4. Increase security in the transfer of technical documentation.

Web Electronic Prototype: The New smart Way for yours electronics Prototypes

Category

- Technics