BOM, Bill Of Material Create it in a correct and standard way, a "good practice" to export the right documentation from your CAD project

Posted on: Dec. 29, 2022, 10:50 p.m.

Our technician Cristiano knows something about it:

”working in an electronic board assembly company, I constantly saw BOMs arriving from the same customer in the most disparate formats. I was forced to go through all the files in order to get on with my work. You don't know how much time I wasted choosing useful information. . . sometimes I found files with 100 parameters and duplicate references and then the really useful information for assembly was missing”.

His words make us reflect on the goodness of our system and on how much they make things easier.

When manually modifying a BOM the error is around the corner, the result? non-functioning boards and wasted time finding bugs and fixing them, by hand, in order to finally go on and get to the car.

Our experience has taught us how important a repeatable and uniquely formatted standard BOM is.

WEP model: Create a custom standard BOM

WEP offers you its standard model in order to optimize the import of the BOM and not create any kind of problem during the production process.

As you can see with a few simple columns we can manage the whole BOM in a totally automated way.

The columns necessary for a correct import of the file are:

Part Number Manufacturer

Drawing reference

Technology (SMD/TH)

Quantity

Smd case

Customer Part Number ( opzionale )

Below we analyze the various items one by one:

Manufacturer Part Number

This is the unique code of a component, it is assigned by the supplier and identifies a component, whether it is active or passive, whether it is a resistor, a capacitor or an inductor, whether it is a differential amplifier or a temperature or pressure sensor. uniquely the component that you have chosen to mount on your board.

Drawing Reference

This item indicates the reference on your wiring diagram where the component must be mounted. For example, let's say you have chosen to mount a 0.1 uF ceramic capacitor from Kemet identified by the code C0603C104K5RACTU, it is inconvenient to report all this code on an electrical diagram, which is too long and not very immediate. Let's say we want to mount it for example in 3 different positions and the reference we wrote on the diagram in those positions is for example C1 for the first position in which it will have to be mounted, C2 for the second position in which it appears and C3 in the third.

C1, C2, C3 will be the Drawing Reference associated with that Manufacturer Part Number.

Technology (SMD/TH)

This, if you are an electronic designer, you should know. . . but you may not be so I'll tell you what it is all the same.

There are mainly two techniques for mounting a component on a printed circuit board. The first to be used historically is the Trough Hole.

In circuits built using this technique, the pins or leads of the components are inserted into some holes of the printed circuit and soldered to the opposite side of the board.

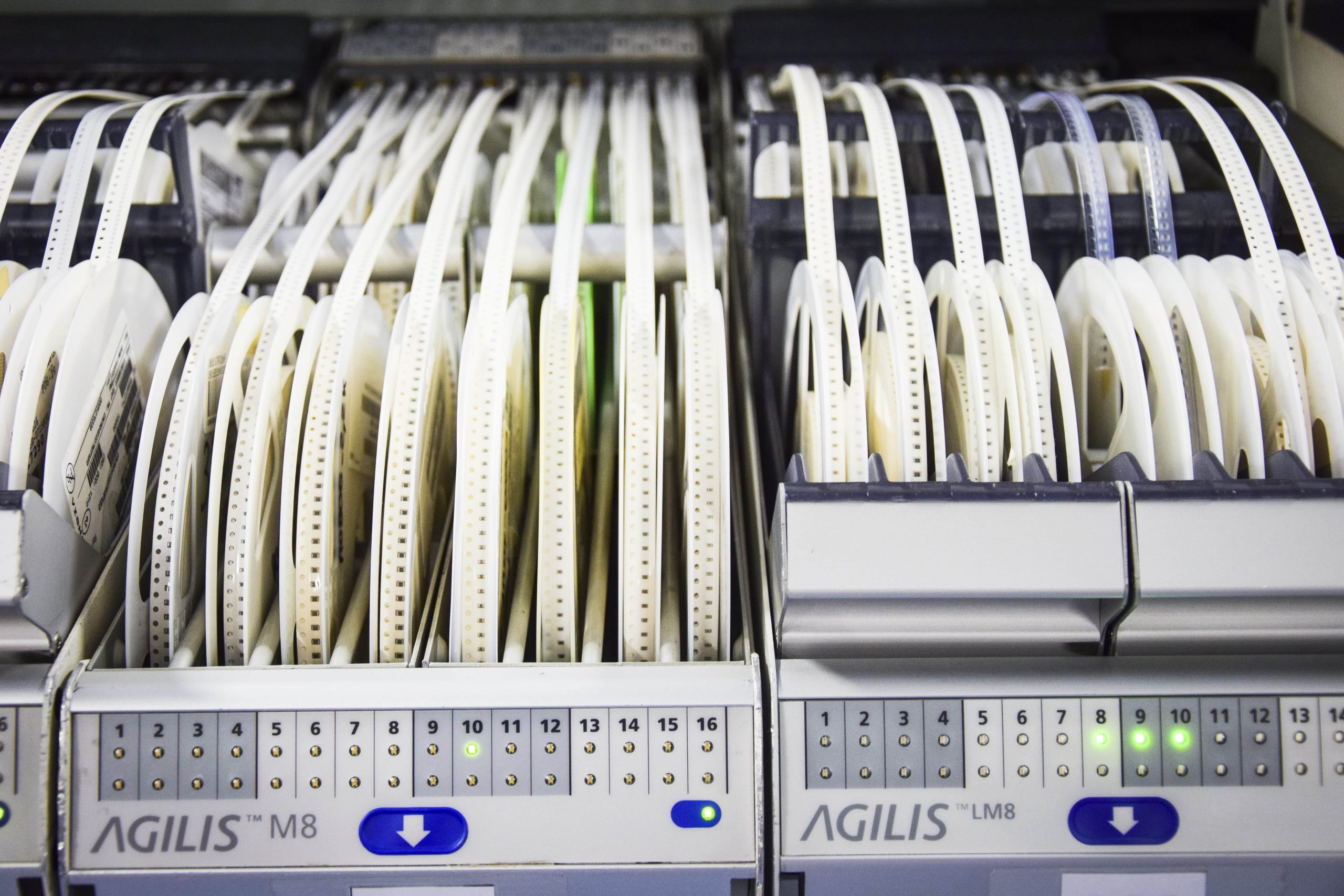

The modern technique is the surface mount technology (SMT acronym) and involves the application of electronic components on its surface without the need to drill holes in the printed circuit. The components that are mounted with this technology are defined as SMD ( surface mounting device ).

Often the boards have a mix of one and the other on the same circuit, for this reason it is an important piece of information regarding the component.

Quantity

We obviously talk about the number of components with the associated part number to be assembled; in the case of the previous example ( C1, C2, C3 ) then the quantity will be 3 components with that code.

Smd case

If the component to be mounted is in SMD technology, a useful piece of information is the dimension of the component which is generally coded and standardised. You can find this information in the characteristics of the component associated with that code or in its Datasheet. Again in the case of the component taken as an example before, the SMD case is 0603. We need this information only for resistors and capacitors by indicating 4 digits (eg 0603, 1206).

Customer Part Number ( optional )

Our experience has suggested that we leave the possibility of inserting a column named "Customer PN" in order to allow you to associate your own coding of the components that could be convenient for you when using management systems or personal databases.

If you already have a BOM file you don't need to redo it to create a standard BOM. . .we're not kidding

Most electronic design software allows you to automatically export a BOM. For this reason, using our platform you can import the file you already have.

Once your file has been uploaded, you just have to indicate the columns that contain the information we mentioned above. The order of the columns will remain at your discretion so as not to have to manually modify any file.

You can try the creation of a project for free, up to the final stages of the order, by visiting our page.

If you like, leave a comment or ask us a question, we will respond as soon as possible to raise any doubts.